Pilot plant

The Footwear and Plastics Technology Centre pilot plant

ofrece a las empresas las siguientes posibilidades:

Thermoplastic formulations.

Thermoset and elastomeric formulations.

Extrusion scale test.

Obtaining masterbaches.

Scaling and testing of materials in monolayer blown film.

Scaling and testing of materials in three-layer blown film.

Testing of materials on calendered film.

BLOWN FILM EXTRUSION MACHINE

The blown film line has a monolayer die width of 60 mm diameter and 0.8 mm of die gap. Depending on the materials, a bubble diameter of 25 cm is achieved.

A three layers concentric die with the same dimensions that the one named above is avalaible. It enables us to produces combinations ABA, AAB or even ABC-

Layers are fed with three extruders. One is type E30Px25 L/D, with 8,8 KW power and compression ratio of 1:1.83. This extruder feed the inner layer or the monolayer film. The other two extruders are type E 20 TH 25 L/D with a compression ratio of 1:3.8

.

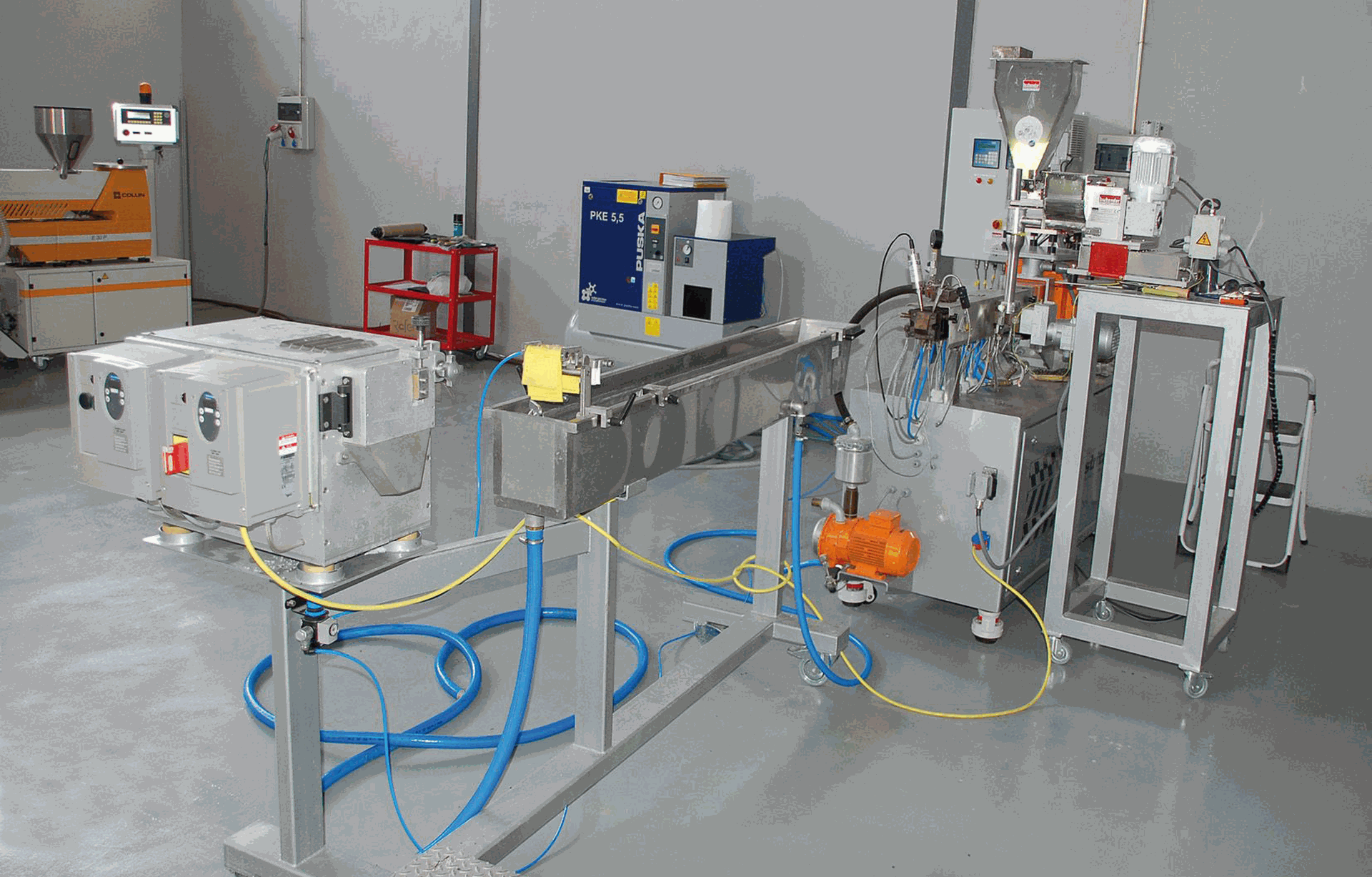

TWIN SCREW EXTRUDER

We dispose of a Leistritz extruder, model ZSE 18HP, twin-screw co-rotating extruder. The screw elements are interchangeable providing different conveying, shearing, or mixing configurations.

The material is cooled in a water bath and cut into granules in a granulator.

The extruder feed is gravimetric with side feed for powder additives.

INJECTION MOULDING MACHINE

Our pilot plant has an Engel injection moulding machine "Victory 200/50 Spex" with a maximum clamping force of 5000 KN (50 tons). It has no columns, which allows the moulding of larger parts due to a larger interior space.

It is equipped with a mould for moulding test specimens, which will allow the study of the properties of new materials through tests in our laboratory.

CALENDERED OR CAST FILM EXTRUSION MACHINE

Slit width of 120 mm, gap adjustment via tractive pressure screws from 0.2 a 2.0 mm. The flat film is feeded by an extruder Type TH E 20 25 L/D, and a screw compression ratio of 1:3,8., then film is stretched in a polished cold roller.